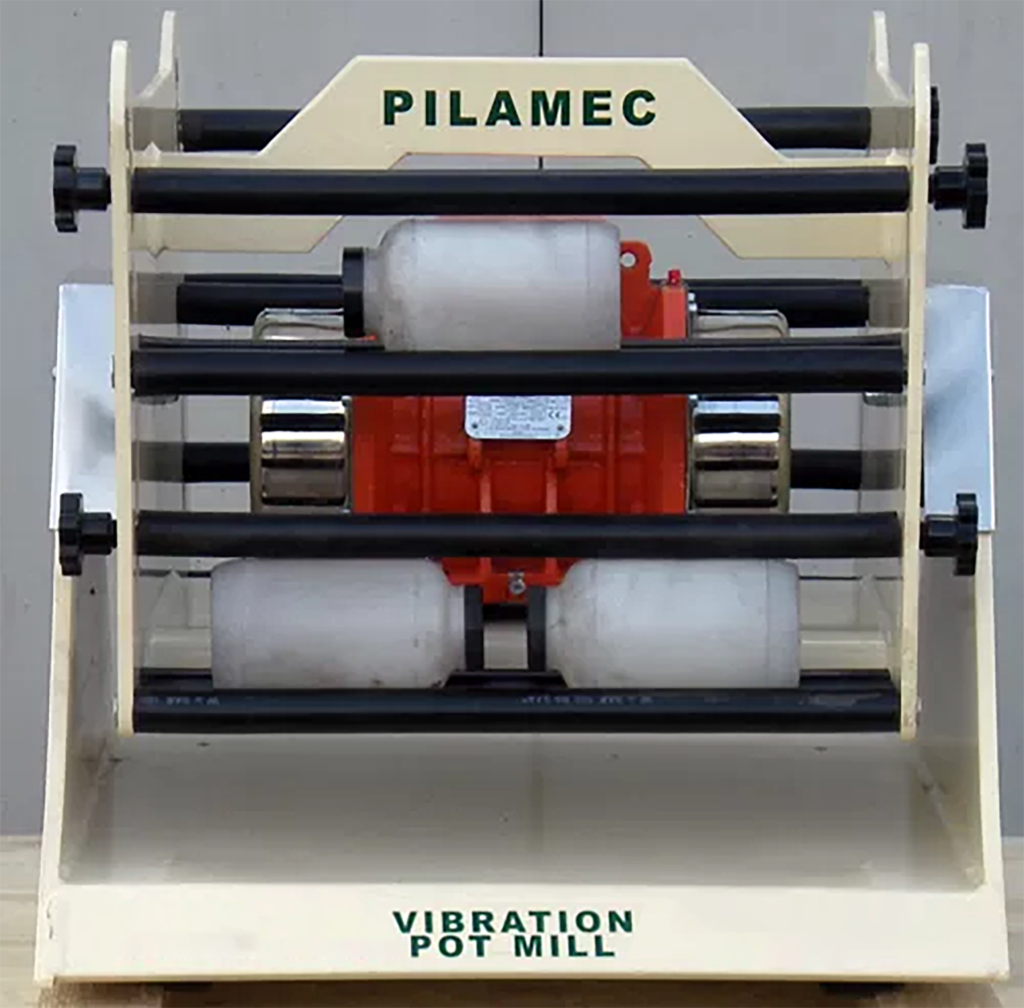

Vibration Pot Mill

A new approach to powder milling, dispersing, blending and homogenizing.

Processing times are typically reduced by a factor of 10 or more. A major contribution to improved laboratory efficiency

- High Energy Vibration Milling

- High Energy Milling means High-Speed Milling

- High-Speed Milling brings results sooner

- Avoids delays that are inevitable with rotary pot mills

- A more rapid evaluation of variables facilitates process optimisations – twenty containers can be loaded on the mill at the same time

- Process Control can be more accurate – multiple samples can be processed many times more rapidly than the conventional equipment

- High Mill Energy permits the grinding of intractable materials too hard or too soft to be handled on rotary pot mills, whether the product is powder dispersion or gel

- High Product Capacity – one Lab Test Pot Mill mill can accept up to four 2000 ml containers or up to twenty 100 ml containers or a mixture of these and intermediate sizes

Brief Technical Specification

Motor : 240V single phase as standard (380/440V 3-phase – optional)

Dimensions : 500mm x 450mm x 450mm

Weight : 85 kgs.

Construction/Actuation

The Lab Test Pot Mill consists of a vibrating chassis mounted to a rigid fabricated steel base using a unique flexible suspension system.

The chassis, together with containers of the product to be ground, is oscillated at approximately 2800 cycles per minute by a proprietary vibration motor system consisting of an electric motor that rotates out-of-balance weights about its axis.

The Lab Test Pot Mill Vibratory Pot Mill is free-standing and supported on four rubber feet. It is best located on the floor.

Operation

The product may be processed in any convenient and rugged cylindrical container. Typical minimum and maximum sizes are 100 and 2000ml.

The mill can be used with various containers and milling media, commonly used polyethylene containers and alumina balls, or porcelain and steel pots and balls can be supplied by Pilamec if required.

Multiple Economic Benefits

Highly cost-effective when compared to alternative equipment.

Cost benefits extend throughout the laboratory – idle time on other equipment awaiting ground product is minimised by speedier processing.

For the Plant Laboratory, the Speed, Flexibility, and Grinding Capacity of the Lab Test Pot Mill can improve operations by:

- Providing the opportunity for a complete approach to the design and optimisation of processes

- Permitting more accurate process control checks to be made during plant operations

The High Productivity of the Lab Test Pot Mill allows many scientists, technicians or students to benefit from its advanced technology while freeing valuable laboratory space for other uses.

Broad Range of Use

Because the Lab Test Pot Mill applies more energy* to the grinding process than rotary pot mills or stirrers, almost any milling task can be completed more rapidly than conventional methods.

Many materials that would not otherwise be processed have been successfully handled using the Lab Test Pot Mill, including very hard and very soft powders, dispersions, and gels.

* Grinding energy depends on several parameters, including the container, the grinding medium, and the setting of the out-of-balance weights (set for maximum acceleration before the fill is dispatched). Grinding energy varies with the third powder of the vibration frequency, depending on the electrical supply frequency and the mill load.