The East Newport Cycle Speedway Club was hit hard by the pandemic and is presently raising funds to renovate its clubhouse. To support the club, Pilamec recently sponsored the club’s Novice Individual event to provide all the club’s new cyclists with their first competitive cycling experience.

The family-orientated East Newport Cycle Speedway Club was started in 2005 and is based in the heart of the Underwood community in Newport, South Wales. The club promotes track cycling for male and female cyclists of any age and ability. The Underwood stadium is home to one of the world’s smallest cycle speedway tracks.

The need to renovate the clubhouse became acute after the pandemic. The club plans to renovate the building to encourage young and old local people to experience the thrills and excitement of track cycling.

“Our team is so enthusiastic about track cycling, and we want to share that passion with the local community,” explained Rob Absalom, Factory Manager of Pilamec and qualified cycling coach at the club. “With Pilamec’s sponsorship, we are another step nearer getting our clubhouse renovated.”

Pilamec – Specialists in Dry Milling, Screening and Blending

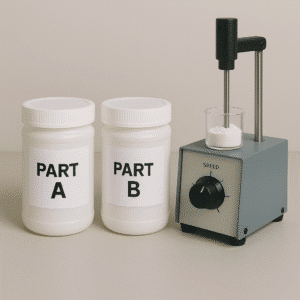

Pilamec specialises in providing batch dry milling, screening and blending of organic and inorganic minerals for companies in industries as diverse as mining, refractories, foundries, recycling, and ceramics. The materials handled range from metals and slags to non-toxic chemicals, with the investigation and test of any product of any type needing size reduction.

For further information, please contact us on:

Phone: 01594 843660

Email: info@pilamec.co.uk