Pilamec has announced a management buyout led by Stephen Mason (left) and Rob Absalom (right), securing the business for both employees and customers.

Pilamec, based in Lydney, Gloucestershire, UK, has announced a management buyout led by Stephen Mason and Rob Absalom. Mason and Absalom have worked for the company for four and seven years, respectively, and have extensive knowledge of the company’s processing capabilities and customer requirements.

Pilamec has been in business for forty-seven years, during which it has been under the ownership of both individuals and groups. Bunting Magnetics, the previous owners, acquired Pilamec Ltd as part of the purchase of Magdev Ltd. However, Pilamec did not form part of its core business, and after one and a half years of ownership, Bunting Magnetics decided to accept the management buyout offer.

Pilamec supplies and processes various-sized granules and powders via specialist crushing, milling, blending and screening operations. The flexibility of the onsite processing plant enables Pilamec to offer batch production of products used in a wide variety of applications, from research and development quantities up to bulk high volumes.

Existing powders, which may only be available in an angular form, can be processed to give them a more spherical shape or to reduce their particle size. Additionally, the company also offers a pre-mix blending of non-standard products, which may be difficult and disruptive in some larger companies’ in-house blending departments. There is also a packaging service available, including customised re-packaging of powders.

Pilamec also trades small quantities of metal powders from primary producers, including iron and carbonyl iron powder; titanium powder; aluminium powder and numerous other types, all of which complement the processing operation.

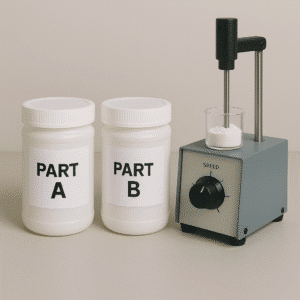

The Megapot milling/blending machine is also manufactured and sold by Pilamec to both university research units and major PM companies. The Megapot is capable of replicating bulk production processing, whether milling or blending and can also be used in laboratories as a test rig for R&D.

Recent investments include additional ball milling capacity, installation of a batch blender, and ultra-sonic sieving equipment for finer powder production. Further investments are already planned.