As more and more customers either require pre-production trial quantities milled to assess results prior to bulk production or organisations just requiring small-lot processing, Pilamec made the decision to invest in a small rotary Ball Mill. Quantities processed can range from just a few kilos up to approximately 20kg.

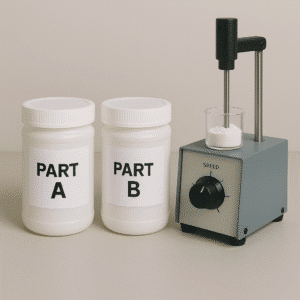

The mill has a nominal capacity of 20kg, dependent on material density and is ceramic-lined to lessen the potential for contamination. Ceramic or metal balls of varying sizes can be used to produce size-reduced lump or powder of numerous materials. Additionally, the mill can be used as a small lot blender, again for experimental purposes or as part of a bulk development programme.

Milling times can be closely monitored to ensure there is no over-milling, and the optimum time to particle size ratio can be determined prior to bulk production, thus maximising product to specification and minimising waste undersized product.

Information gathered from the milling process can be used to ensure accurate costing for bulk processing customers and ensures material is processed in the most cost-effective way.

For companies with R & D departments and Universities, the small quantity required for processing can make this an attractive opportunity to get specific powders from items not usually available, whether they be metal; ceramic; chemical; glass or other items. Already organisations have been able to move forward with new projects, which were proving difficult to start due to the non-availability of powders to the correct sizing.

Allied with the Laser Analyser for accurate particle distribution measurement, the small test mill is proving a very worthwhile investment both for Pilamec and its customers.

For further information regarding the test mill capabilities, please complete this contact form, and one of our experts will contact you to discuss your project further.